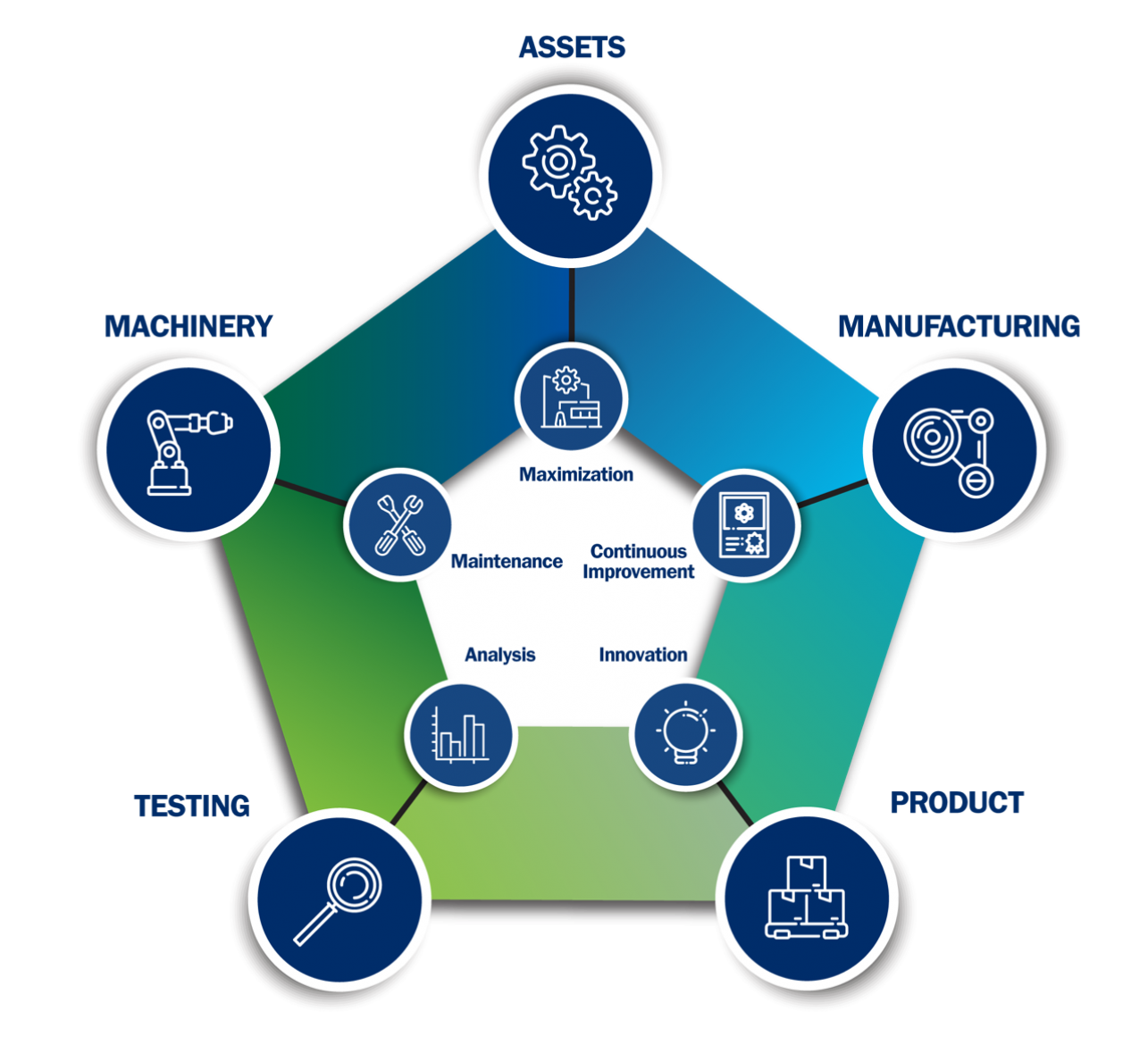

Today, successful manufacturers take a more holistic approach in managing their productivity, product quality, cost efficiency, and innovations. They realize that in order to stay competitive in the rapidly-changing market, one has to push for the next horizon of operational efficiency.

With over 20 years of experience, Promet Consultancy Company Limited provides a wide range of technical advisory services to manufacturers and die-casters, optimizing an enterprise’s physical assets and laying a solid foundation for their profound growth in the future.

We meet our clients anywhere they are in their journey to become highly cost efficient and highly productive, providing everything from specific expertise on discrete issues to holistic transformations spanning production floor design, build, implementation, capability building and ongoing support.

See Our Solutions for

A well-designed production site is crucial to productivity.

Our experts could make recommendations to the layout of production lines, machinery selection, capacity planning, bidding arrangement, and the parameters of process monitoring. Our services also include calibration of equipment, productivity and environmental assessment to expedite our client’s production lines setup.

Talent is an important asset.

Operators, technicians, and engineers need to be equipped with the latest, essential skills and knowledge such as green manufacturing, lean manufacturing, quality control for their daily operation. Integrating both theory and practice, Promet’s workshops help die-casters and manufacturers build their technical capacity. Learn More

Eliminating waste, variability and inconsistency in quality can be achieved with better production planning, process monitoring and mould design.

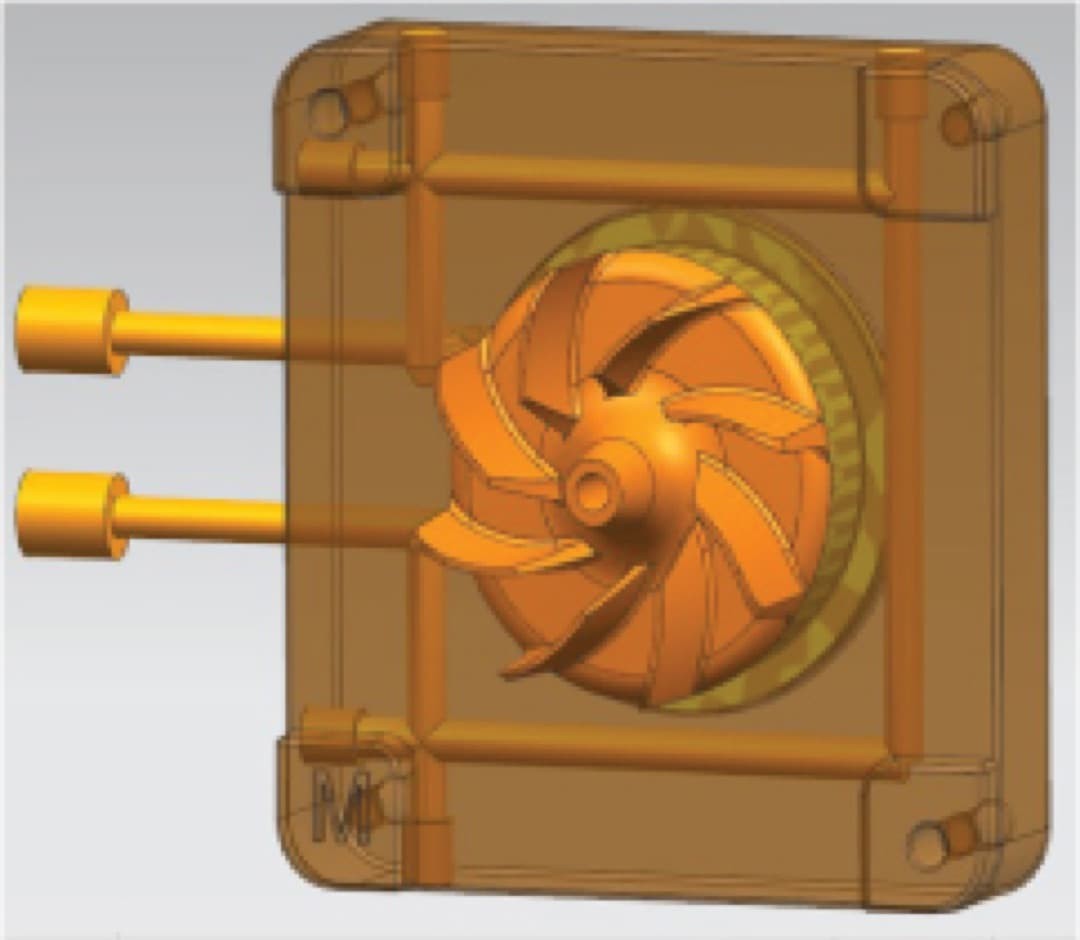

In fact, the earlier Promet is involved, the more contribution Promet can bring. Addressing the key areas of improvements, our professionals offer recommendations ranging from material and supply selection, manufacturability of the DFM product, mould engineering, to optimization of production parameters.

The time of mould development can be significantly shortened by making use of 3D printing technology. Besides, 3D printing technology lets engineers optimize the design of cooling channels which can be printed to any shape and require minimal postprocessing or assembling to achieve similar tool life and greater flexibility.

Please contact our Promet’s specialist to learn more about our solutions for precision manufacturing.

3D Mould Printing Technology

Traditional Way of Mould Development

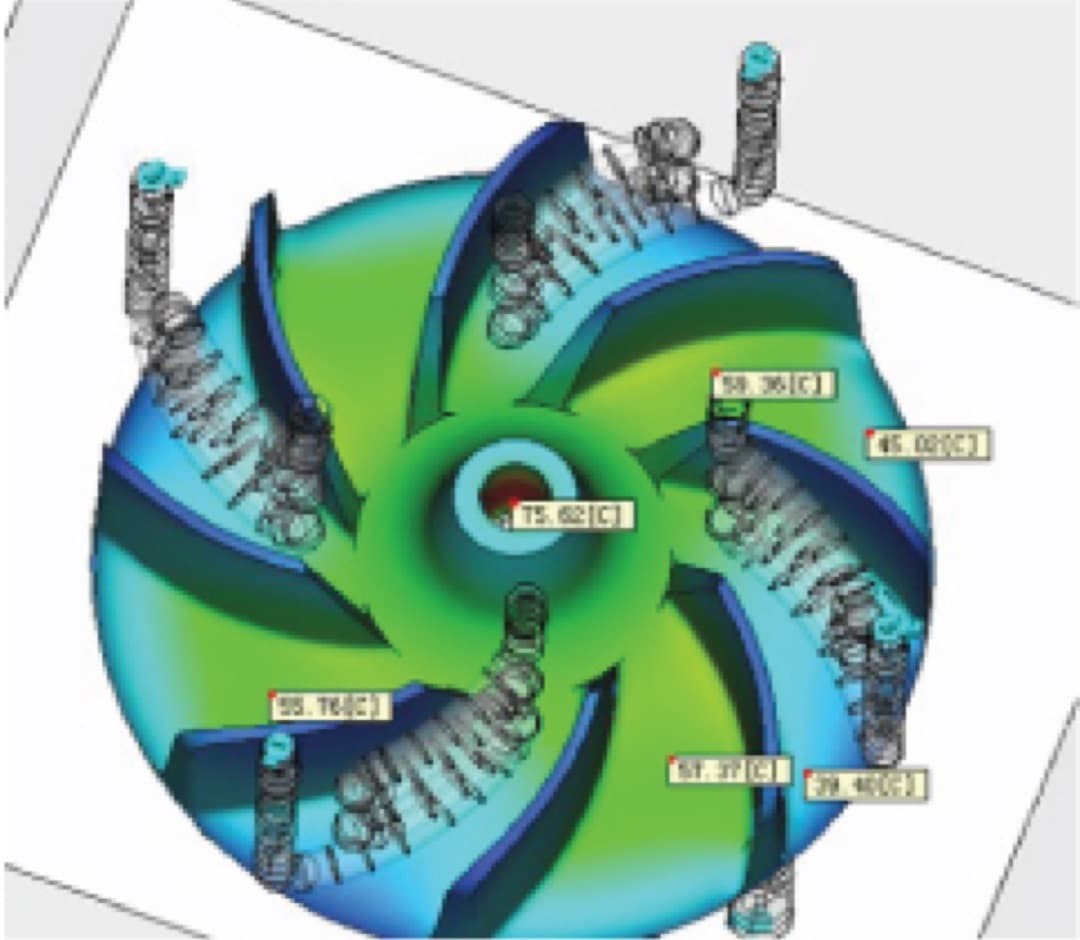

Advanced software and tools like Flow-3D provide detailed insights into filling and solidification of the cast part while tracking various defects like porosity and flow marks.

Promet’s experienced engineers leverage modern digital and robotic technologies to help our client’s operation transit to Industry 4.0. Our services of developing mould for mass production reduce our client’s development time on the plant floor, escalate their productivity and shorten time to market.

Promet’s specialists develop a series of scientific cost and quality monitoring and analytical models, specifically for die-casting and manufacturing industries, to keep track with the factory’s dross, cycle time, rate of waste, die life, energy efficiency, etc.

By transforming the data to quantitative indicators, Promet benchmarks the factory’s performance with the industry’s best practice and share the findings with our clients.

The first laboratory in Hong Kong accredited in Metals and Metallic Alloy category, and one of the approved London Metal Exchange (LME) Listed Samplers and Assayers (LSA), Promet is widely recognized of its professionalism in testing in metals.

Apart from composition analysis, Promet conducts die-casting furnace sampling and analysis and coordinate the entire process of product certification for our clients.

Common metal products defects like blisters, fractures, hard spots are just “symptoms”. To fix them, it takes an in-depth testing and analysis to identify the root cause.

Promet’s laboratory is fully equipped to provide metallographic, metallurgical, chemical and mechanical analyses. By revealing and examining the microstructure, composition as well as mechanical performance, our metallurgists are able to provide a reliable result and practical solutions to resolve our client’s problems.

Regular maintenance on plant and equipment can prevent problems arising and reduce unexpected breakdown.

Promet’s annual inspection program offers objective evaluation of critical performance parameters regarding materials handling, die-casting process, and occupational safety. The findings will be illustrated along with a review of safety precautions and standard operating procedures, sustaining the enterprise’s high level of product quality and work safety standards.

Tailor-made for die-casting and its ancillary equipment, this program covers the checkup of injection power, plunger velocity and the setting of 1st/2nd stage speed based on the client’s production needs. Systematic care, repair and replacement of critical components will be conducted to mitigate the risks of production disruption caused by fatigue, wear or failures of machinery.